What Are The Details To Know When Buying A PC Board?-

What Are The Details To Know When Buying A PC Board?

2024-06-17

When buying a polycarbonate (PC) board, there are several important details to consider to ensure that you select the right product for your specific needs. Here are some key factors to keep in mind:

1.Weight

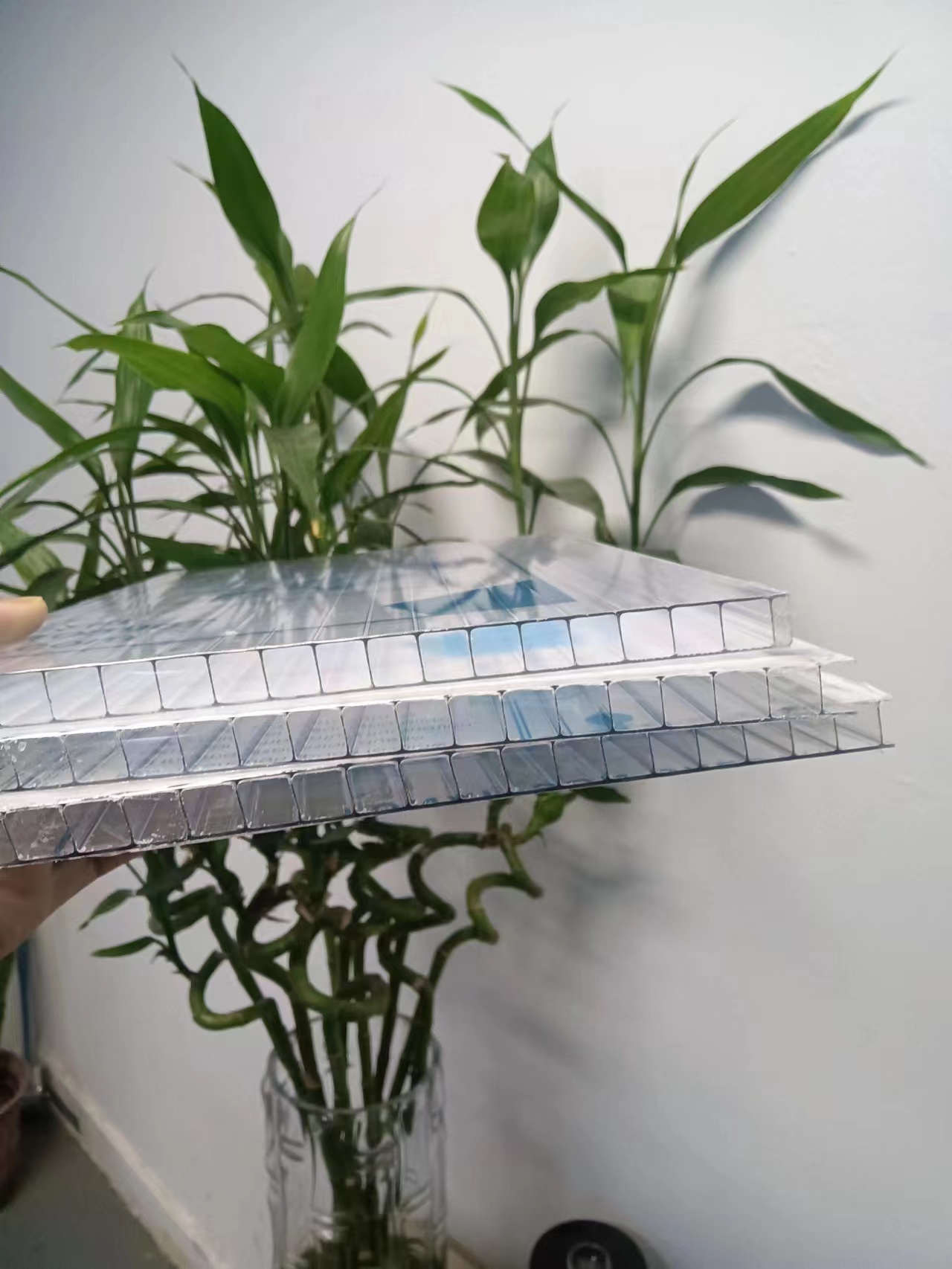

You may often hear the term "weight", so what harm is there in reducing weight? The thicker the board weight, the more raw materials it uses for processing, and the better the quality. Everyone must pay attention to this when buying and choosing.

2. Light Transmittance

The light transmittance of PC board is not static. Take the fully transparent board as an example. Generally, the light transmittance of two-layer transparent board is about 80%, while the light transmittance of endurance board is around 90%. The light transmittance will gradually decrease with the change of the thickness, number of layers, structure, and color of the sheet.

3.Warranty Period

PC board has a certain period of warranty period, including the warranty period of three years, the warranty period of five years, and the warranty period of ten years. Other materials are an important element in the identification of PC boards. Customers can choose products with a suitable warranty period. It must be noted that if you do not purchase PC sheets from genuine websites, some illegal shops will likely fake and inferior products, causing you to suffer losses.

4. Ageing Resistance

What is the basic principle of PC board ageing resistance? PC materials belong to chemical materials. The direct ultraviolet light in the sun will promote the transformation of polycarbonate structure, which will cause yellowing and even brittle cracks after two years. Therefore, people must co-extrude a coating on the surface of the board to avoid ultraviolet light. The basis for this is that the UV coating of PC sheet co-extrusion is an ingredient of professional sun protection.

5. Actual Application

Is the thicker and higher the pc sun board? The reference answer is denied. We must fully consider the act